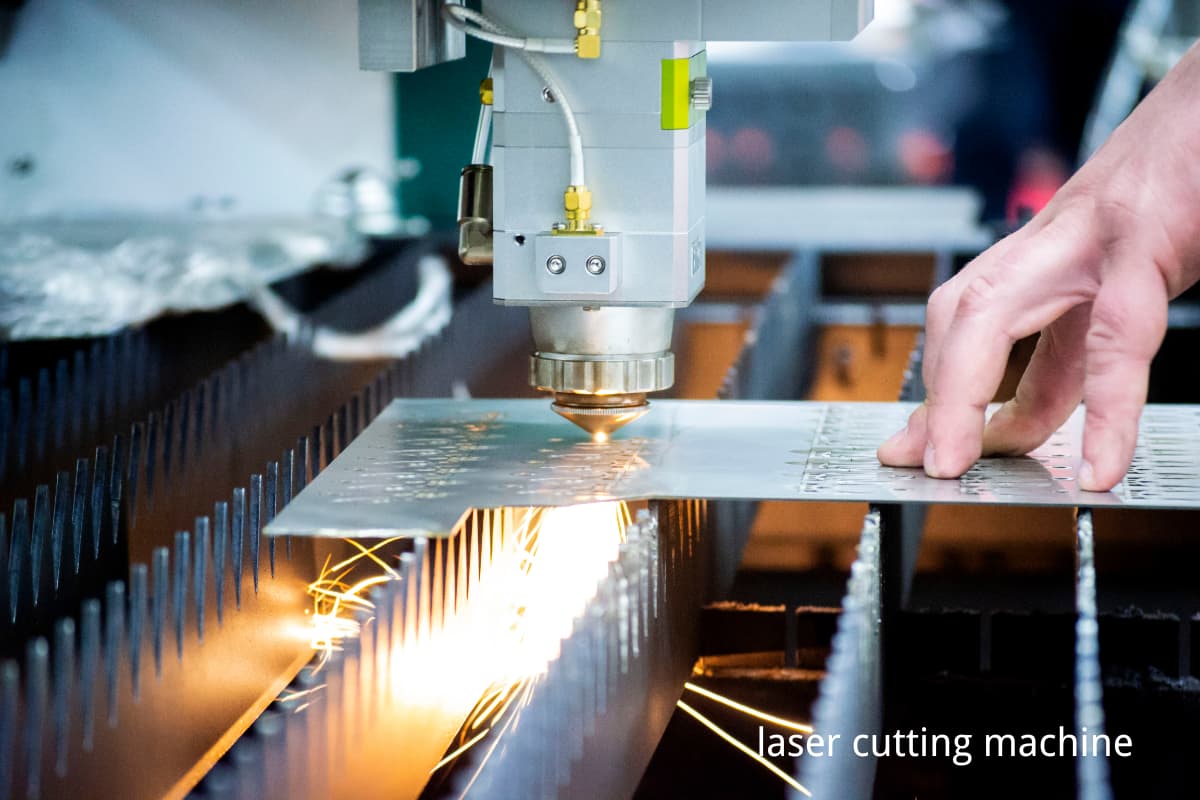

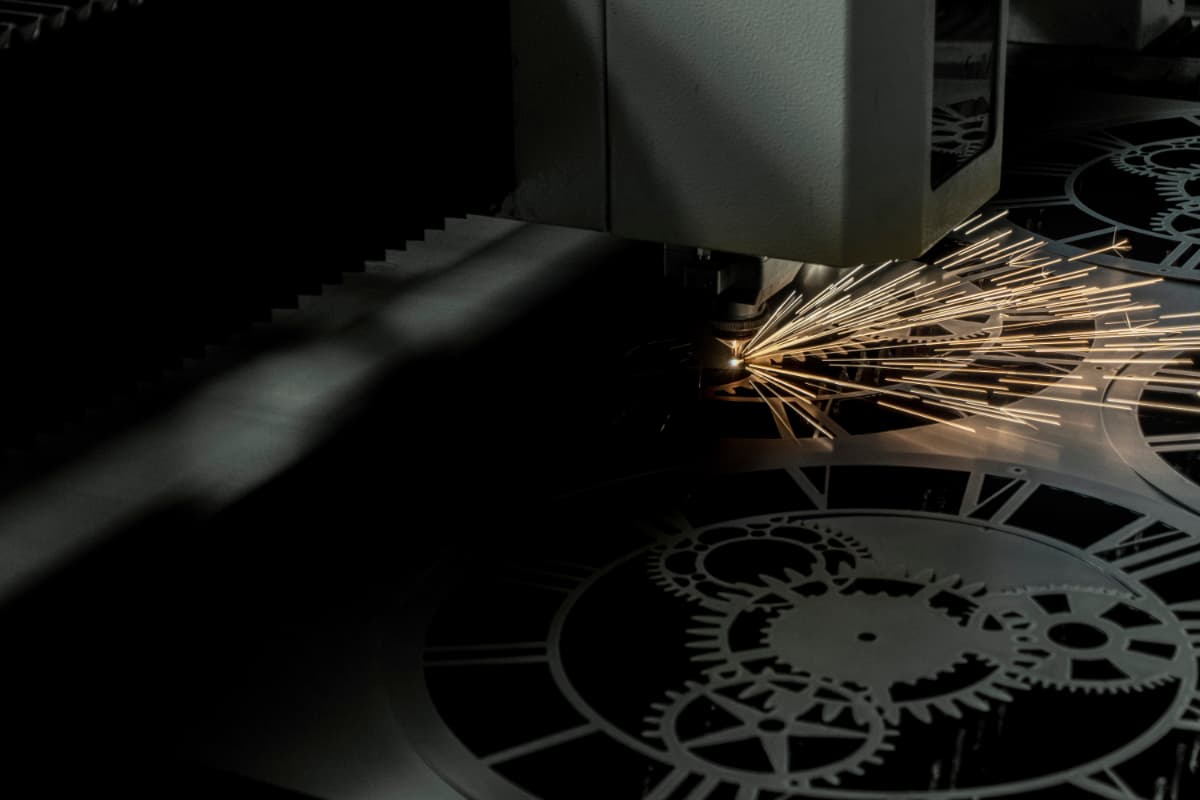

A laser cutting machine, as a kind of equipment, utilizes high-power density laser beams to cut, engrave, and punch. Its working principle is that the laser beams generated by the generator irradiate the surface of workpieces to melt, evaporate, and burn the material's surface layer. At the same time, after the high-pressure gas blows away the molten material, the cutting is finished. Laser-cutting technology has been widely applied in metal processing, electronic fabrication, the automotive industry, aerospace and advertising, possessing advantages of high speed, accuracy, narrow slits and small heat-affected zones. Using a laser-cutting machine correctly can improve processing efficiency and product quality, prolong the product lifespan, and lower maintenance costs. On the contrary, improper operation may damage machines, decrease processing quality and even lead to safety incidents. Thus, it’s vital for the operators and business managers to have a deep understanding of laser cutting machines’ working principles, operation procedures, safety precautions and maintenance. The article aims to provide a thorough and detailed user guide on laser-cutting machines. Based on the guide, readers will acquire the basic knowledge, operation procedures and advanced tips and tricks. No matter you are a beginner or a sofisticated operator, the article can provide you with valuable information to improve the efficiency and safety of laser cutting machine utilization. To learn and understand a laser cutting machine, we should answer three questions: What’s a laser cutting machine, and how does it work? How many types of laser cutting machines are there according to lasers? What’s the application of laser cutting machines in various industries? (1)Definition The laser cutting machine is a piece of equipment that utilizes high-power density laser beams to cut, engrave, and punch. Its working principle is that the laser beams generated by the generator irradiate the surface of workpieces so as to melt, evaporate, and burn the material's surface layer. At the same time, after the high-pressure gas blows away the molten material, the cutting is finished. (2)Basic components A laser cutting machine is mainly composed by the following parts: According to laser types, the laser types of laser cutting machines can be divided into CO2 laser cutting machines, fiber laser cutting machines, and YAG laser cutting machines. (1)CO2 laser cutting machines It utilizes CO2 gases as a laser medium, suiting for non-metal material cutting and some metal material cutting. (2)Fiber laser cutting machines Utilizing fiber as a laser medium, it boasts high efficiency, energy savings and low maintenance costs, suitable for various metal materials. (3)YAG laser cutting machine It utilizes neodymium-doped yttrium aluminium garnet crystal as a laser medium, suitable for high-precise and exquisite processing. (4)Comparison This table provides a comprehensive comparison of the three types of laser cutting machines, highlighting their key features, advantages, and disadvantages. Further, I’d like to share you a simpler table to have an even more intuitive comparison. Generally, laser cutting machines are widely applied in many sectors. (1) Metal processing They can cut stain steel, stainless steel and aluminum alloy and are suitable for mechanical manufacturing and sheet metal processing. (2) Electronic fabrication They can cut circuit boards and electronic components, so they are suitable for electronic product production and assembly. (3) Automotive industry They are capable of cutting vehicle components and body parts to improve production efficiency and product quality. (4) Aerospace They are used for cutting aerospace materials and meet high speed and strength processing requirements. (5) Advertising They can cut acrylic, wood and plastic for the production of billboards and signs. Let's view a short video! (1)Types of materials suitable for laser cutting Laser cutting machines can cut all kinds of materials, including metal and non-metal materials. Commonly, here are some materials suitable for laser cutting: (2)Material preparation tips (1)Proper placement and securing (2)Adjusting the laser head (1)Power and speed settings (2)Focus and alignment (1)Importance of test cuts (2)Analyzing test results and adjustments (1)Monitoring the cutting process (2)Post-cut inspection and adjustments Based on the step-by-step operation guides above, operators and beginners can use laser cutting machines correctly and safely and guarantee cutting performance and efficiency. Speed and precision are two key factors during the cutting process. To maximize cutting results, a balance between speed and precision should be achieved during cutting. (1)Balancing speed and precision Laser power directly affects cutting speed and quality. High power improves cutting speed, but decreases cutting edge smoothness. On the contrary, low power improves cutting precision but decreases cutting speed. Therefore, proper laser power adjustment according to material thickness and type is vital. The focal length determines the location of laser beam’s focal point. Appropriate focal length can ensure that laser beams form a small spot on the material surface so as to improve cutting precision. Normally, shorter focal lengths suit thinner materials while longer ones for thicker. The proper cutting paths can reduce the movement distance of a cutting head, improving cutting efficiency. CAD software-designed cutting paths should avoid unnecessary turns and repeatitive cutting. Assist gases, such as oxygen, nitrogen or air, can help clean the molten during cutting, improving cutting quality. Different materials entail different assist gases. For example, oxygen suits carbon steel cutting while nitrogen suits stainless steel and aluminum cutting. (2)Cutting Techniques for Different Materials Different materials present different features, which needs to adopt different cutting techniques This table provides a detailed reference for the choice of assist gas, the function of the assist gas, laser power, cutting speed, and other considerations for cutting different metal materials with a laser. This table provides a quick reference for the choice of assist gas, laser power, cutting speed, and key considerations when laser cutting various non-metal materials. This table provides a quick reference for the choice of assist gas, laser power, cutting speed, and key considerations when laser cutting various non-metal materials. (1)Custom designs and projects Laser-cutting technology is not only widely applied in industrial manufacturing but presents significant potential in creative and customized projects. Laser cutters can cut wood, metal and acrylic precisely and allow for personalized furniture design. Designers can make intricate patterns and structures using laser cutting machines to provide personalized furniture design service. Laser cutters can make exquisite artworks, such as Such as carvings, decorations, and lighting fixtures, etc. Artists can cut precise patterns and details and make unique artworks. Laser cutting can be used to make construction, mechanical, and tool models. The technology allows each part to be cut precisely and assembled quickly. (2)Business opportunities Laser-cutting technology brings about many commercial opportunities. Here are business opportunities you can explore with the help of laser cutting machines. You can provide customized products, such as customized furniture, gifts and decorations. Laser cutting technology can meet personalized demands and provide high-quality customized profucts. Laser cutting technology suits small batches of production and can quick response to market demands. Enterprises can use laser cutting machine technology to carry out small batches of production, lower production costs and improve product efficiency. Open a creative studio, provide laser cutting equipment and technical support for designers, artists and makers. The creative studio can become an innovative platform for laser cutting technology, promoting the combination of creative design and technical application. In summary, laser cutting technology not only plays a significant role in industrial manufacturing but also demonstrates enormous potential in creative design and commercial applications. By continuously optimizing cutting speed and quality, exploring creative applications of laser cutting can achieve more efficient and precise cutting effects, opening up more business opportunities. According to the step by step guide for laser cutters’ users, you can start a journey of exploring laser cutting technology. ADH Machine Tool offers a variety of top-tier laser cutting machines to meet all your cutting needs. Our dual-use fiber laser cutting machines (ULFT and ULET) can not only cut sheet metal, but also tubes with diameters from 20-320mm, satisfying diverse processing requirements. For customers who require high precision cutting, our precision laser cutter (ULJM) is specifically designed for cutting non-ferrous metals such as copper, nickel, cobalt and precious metals like gold, silver and platinum with a thickness range of 0.1-4mm. Choose ADH laser cutters for exceptional performance and reliable quality that will boost your business. Contact our professional sales team now for a free quote and more information! Bleaching Earth For Refinery,Special Bleaching Earth For Refinery,Refinery Special Bleaching Earth,Special Refinery Bleaching Earth XUYI BOTU ATTAPULGITE CLAY CO.,LTD , https://www.xuyibotu.comI. Introduction

II. What is a Laser Cutting Machine?

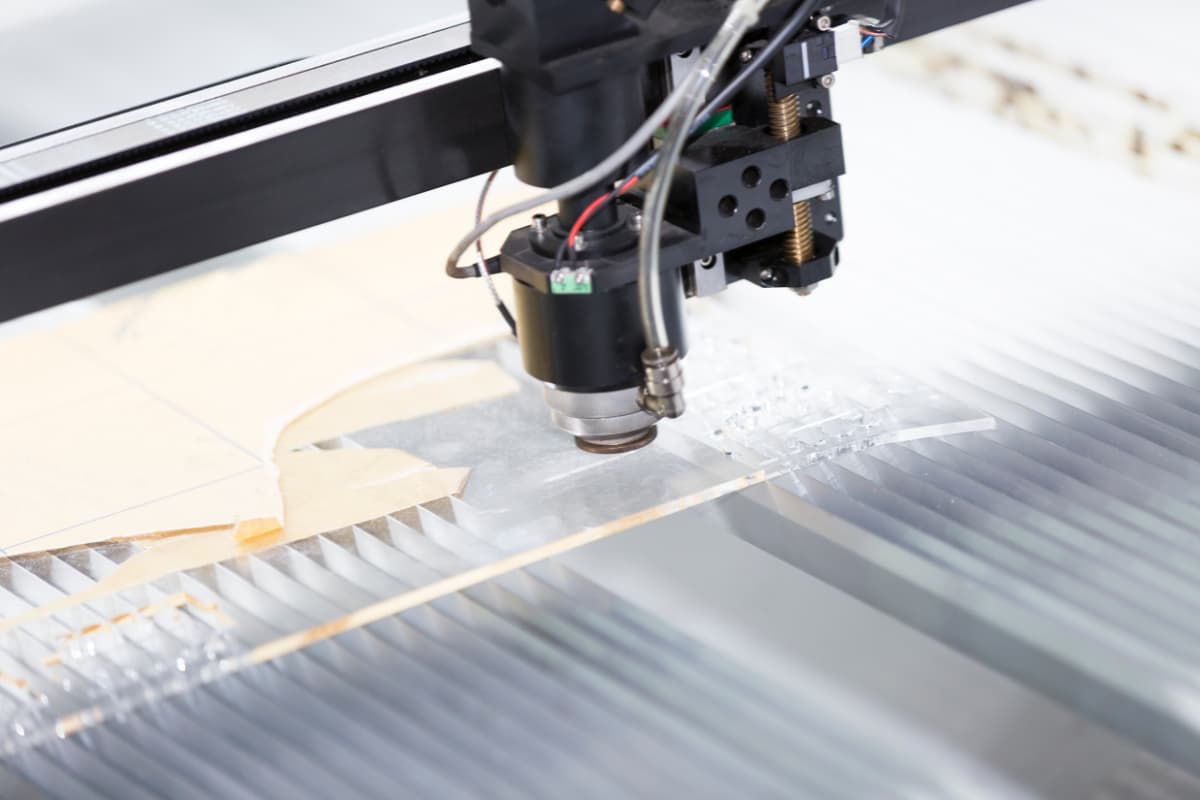

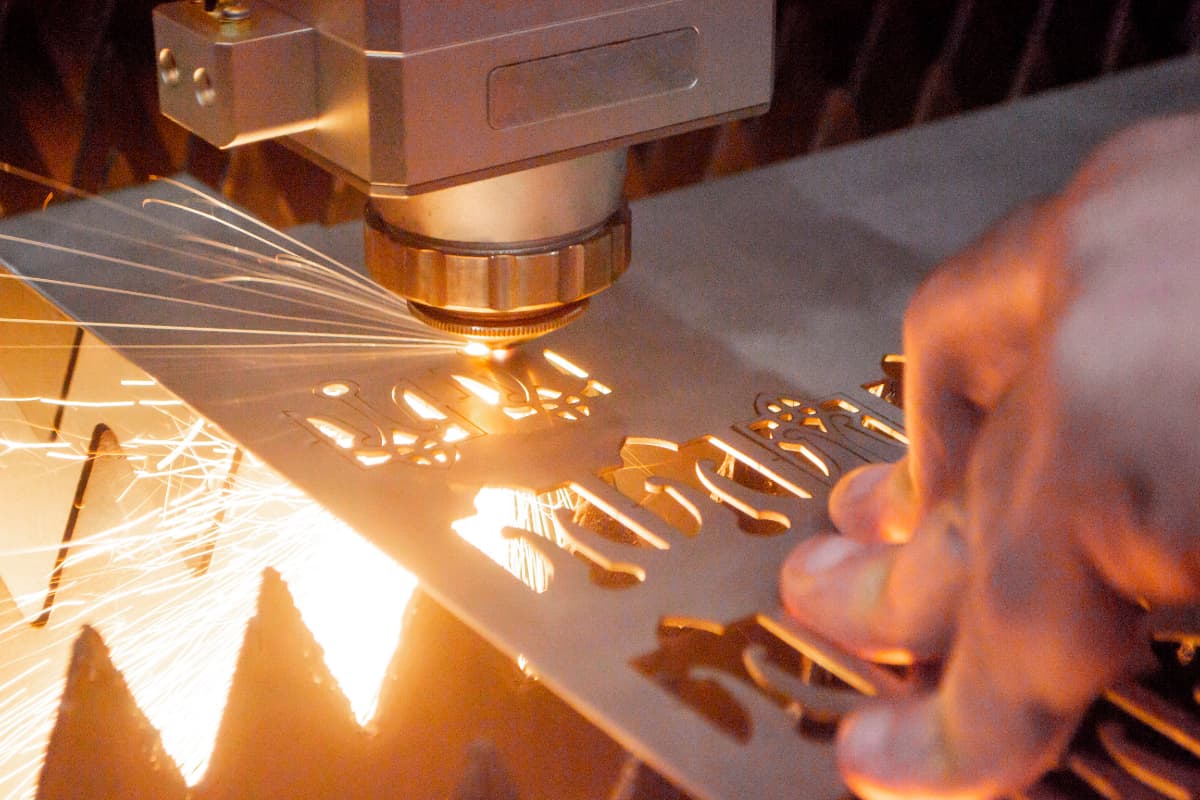

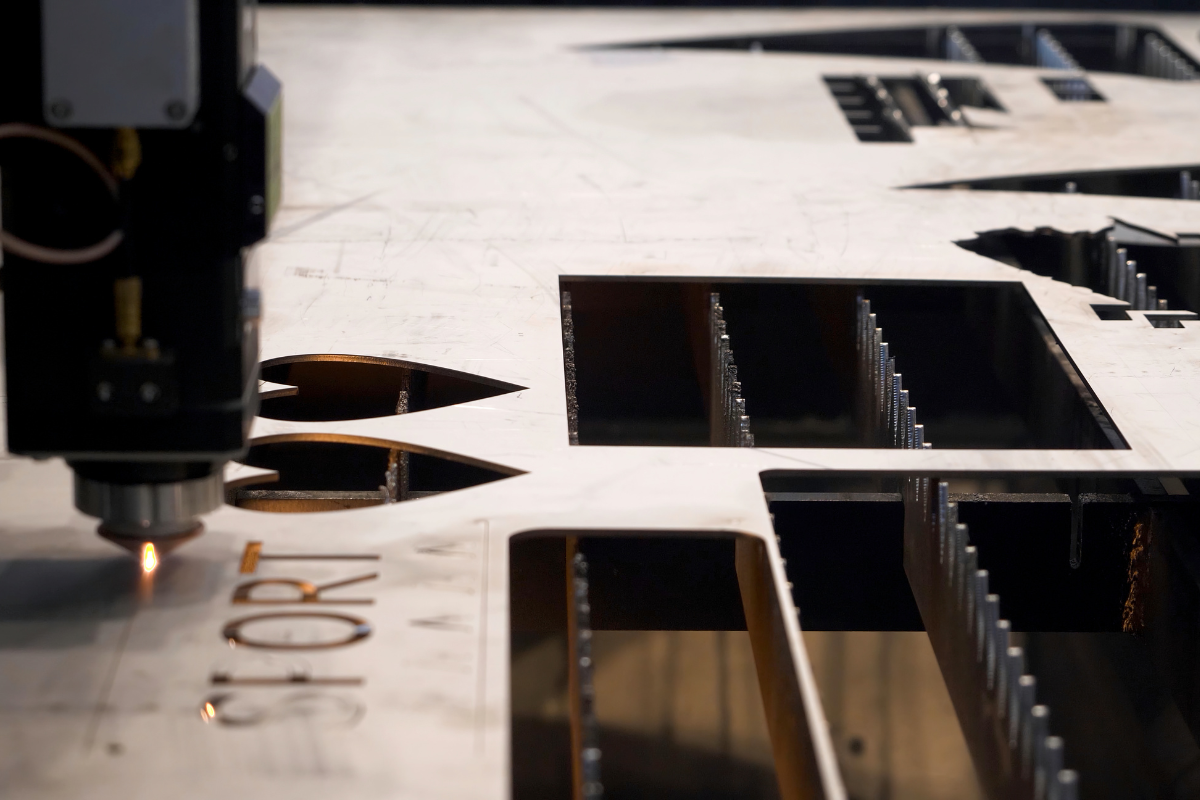

1. Definition and basic components

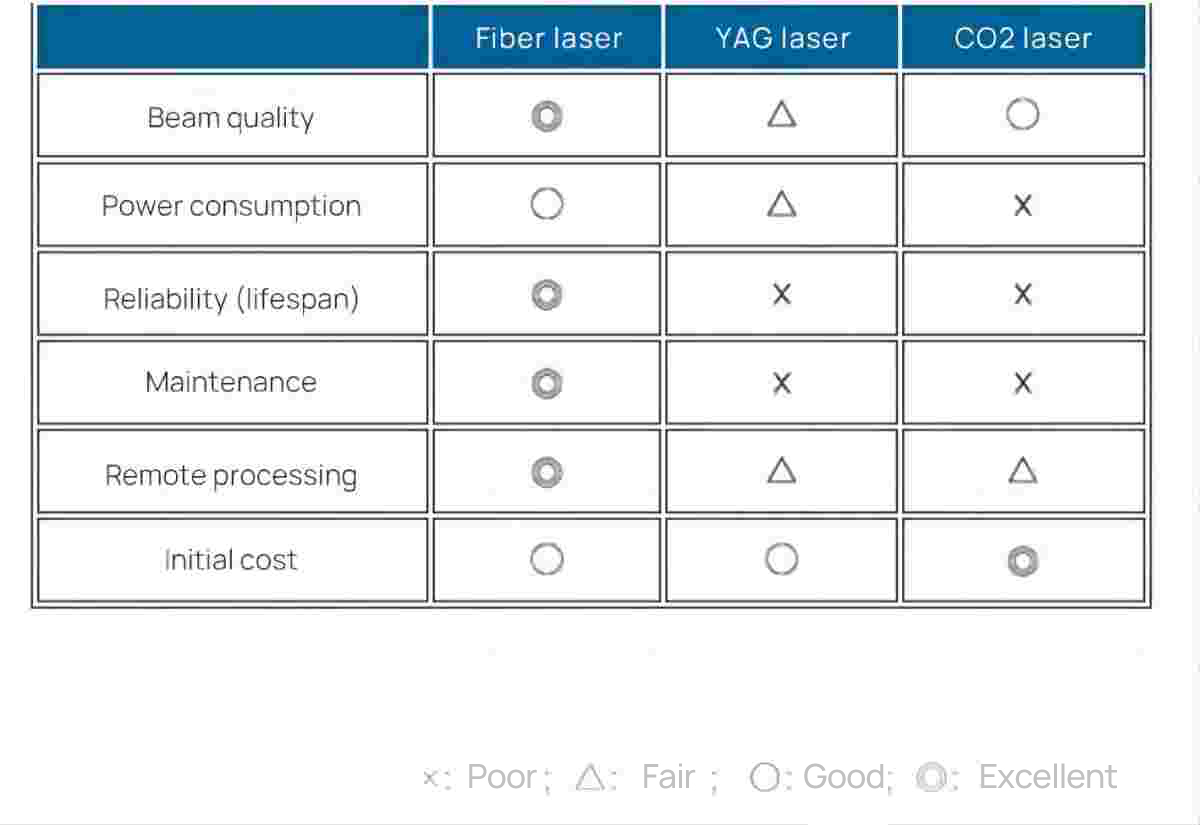

2. Types of laser cutting machines (CO2, Fiber, Nd:YAG)

Feature/Aspect CO2 Laser Cutting Machine Fiber Laser Cutting Machine Nd:YAG Laser Cutting Machine Laser Medium CO2 gas Optical fiber doped with rare-earth elements Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG) Wavelength 10.6 micrometers 1.064 micrometers 1.064 micrometers Material Suitability Non-metals (wood, acrylic, plastic), some metals Metals (steel, aluminum, copper, brass) Metals, ceramics, some plastics Cutting Speed Moderate High Moderate Cutting Thickness Suitable for thicker materials Best for thin to medium-thickness materials Suitable for thin to medium-thickness materials Beam Quality Good Excellent Good Efficiency Lower (10-20%) Higher (25-30%) Moderate Maintenance Requirements Higher (requires regular maintenance of optics) Lower (solid-state, fewer moving parts) Moderate (requires maintenance of flash lamps) Initial Cost Moderate Higher High Operating Cost Higher (consumables like gas, optics maintenance) Lower (less consumables, higher efficiency) Moderate Lifespan of Laser Source 8,000-15,000 hours 50,000-100,000 hours 8,000-15,000 hours Cooling Requirements Requires water cooling Air or water cooling Requires water cooling Applications Signage, woodworking, plastics, textiles Automotive, aerospace, electronics, metalworking Medical devices, precision engineering, jewelry Advantages Versatile, good for non-metals, lower initial cost High efficiency, low maintenance, excellent for metals High precision, good for both metals and non-metals Disadvantages Higher operating cost, lower efficiency Higher initial cost, best for metals High initial and operating costs, moderate efficiency

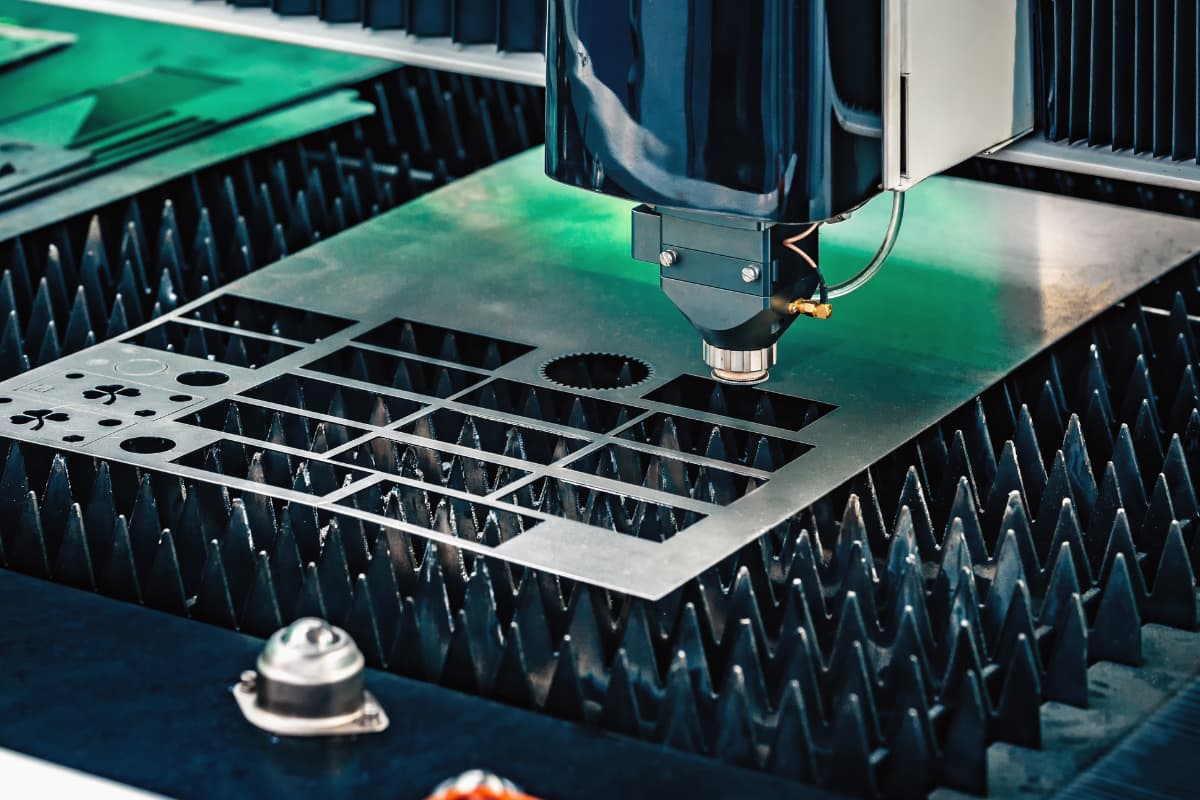

3. Applications in various industries

III. Step-by-Step Guide to Use a Laser Cutting Machine

Step 1: Preparing the Material

Step 2: Loading the Material

Step 3: Configuring the Machine Settings

Step 4: Running a Test Cut

Step 5: Executing the Final Cut

VI. Advanced Tips and Tricks

1. Optimizing Cutting Speed and Quality

Metal Material Assist Gas Assist Gas Function Laser Power Cutting Speed Other Considerations Carbon Steel Oxygen Reacts with carbon steel to produce high temperature, increasing cutting speed Medium to High Medium Control laser power and cutting speed to avoid excessive melting Stainless Steel Nitrogen Prevents surface oxidation, maintains smooth cutting edges High Slow Ensure cutting quality, avoid edge oxidation Aluminum Nitrogen or Air Prevents oxidation, adapts to high reflectivity High Medium Pay special attention to laser beam focusing to prevent reflection damage to the laser

Non-Metal Material Assist Gas Laser Power Cutting Speed Considerations Wood Air Low Fast Avoid excessive burning Acrylic Air or Nitrogen Medium Medium Ensure smooth cutting edges Fabric Air Low Fast Avoid melting or burning 2.Creative Uses of Laser Cutting

V. Conclusion